Infection control is a basis of patient safety, and sterilization rolls play a crucial role in maintaining the sterility of medical instruments. However, improper handling, storage, or sealing of these rolls can compromise their effectiveness. Here’s a closer look at common issues with sterilization rolls and the best practices to overcome them in healthcare settings. It also includes sterilization and proper use of sterilization rolls, is a cornerstone of patient safety in healthcare settings. It aims to prevent the spread of

infections, reducing patient morbidity, mortality, and costs. Sterilization rolls, containing sterilized medical instruments, are a crucial element of this process, ensuring that equipment used in procedures is free from pathogens.

1. Incomplete or Weak Sealing

Issue: One of the most frequent problems is poor sealing due to incorrect temperature settings or inadequate sealing machines.

The sealing process is crucial in ensuring the sterility of the contents. If the rolls are not properly sealed, contaminants can enter the package. This may occur due to inadequate heat-sealing equipment or user error during the sealing process.

Best Practice: Use heat-sealers specifically designed for medical packaging and ensure they are calibrated to the recommended temperature (usually around 160 – 165°C for CPP/PAT film). Regular maintenance of sealing equipment is essential.

2. Tearing or Delamination

Issue: Low-quality rolls may tear or delaminate during opening, risking contamination.

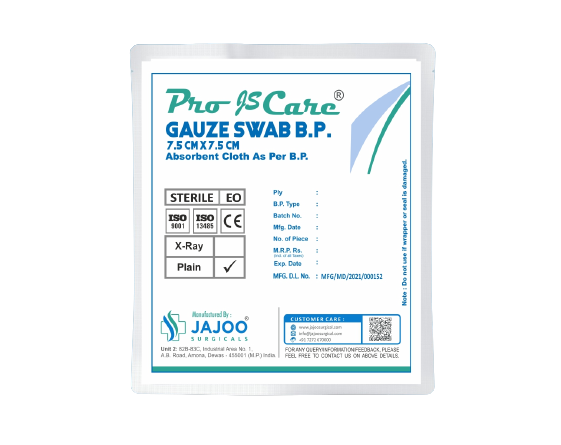

Best Practice: Choose rolls made from durable, medical-grade paper and reinforced film. Jajoo Surgicals sterilization rolls are engineered for easy peeling without delamination, ensuring safe access to sterile instruments.

Tearing or delamination of sterilization rolls, pouches, or packs can compromise their sterility and potentially lead to contamination. This happens because a compromised barrier system allows microorganisms to penetrate and contaminate the contents. Proper handling, storage, and inspection are crucial to prevent this.

3. Misinterpretation of Sterility Indicators

Issue: Faded or unclear indicators can cause confusion about whether instruments are properly sterilized. This happens because a compromised barrier system allows microorganisms to penetrate and contaminate the contents. Proper handling, storage, and inspection are crucial to prevent this.

Best Practice: Use sterilization rolls with high-contrast, dual-process indicators. Jajoo’s rolls include both Steam and ETO indicators that clearly change color after exposure.

4. Overstuffing or Undersized Packaging

Issue: Overloading a pouch or using the wrong size roll can lead to rupture during sterilization.

Best Practice: Select appropriately sized rolls with extra space around the instruments for air removal and proper sealing.

By implementing these best practices and choosing high-quality products like Jajoo Surgicals sterilization rolls, healthcare facilities can significantly improve infection control and ensure safer patient care.