Introduction:

In the world of surgical care, few items are as indispensable as the gauze swab. From dressing wounds to controlling bleeding during surgery, gauze swabs play a crucial role in maintaining hygiene, preventing infection, and aiding in patient recovery. As India’s healthcare infrastructure continues to expand at a rapid pace, the demand for high-quality Gauze Swab Sterile products has witnessed unprecedented growth.

Gauze swabs are essential in modern healthcare for their role in wound care, surgical procedures, and general medical applications, serving as a sterile barrier to protect wounds, absorb fluids, and clean injuries. Their versatility allows them to be used for cleaning wounds, applying medication, and providing a dressing, making them a critical component of both emergency first-aid and complex surgical environments.

This rise is driven not only by the increasing number of surgeries performed each year but also by the country’s focus on advanced medical standards and infection control practices. Consequently, gauze swab manufacturers India are stepping up production capabilities, implementing global quality standards, and offering innovative sterile solutions for hospitals and clinics across the nation.

This detailed guide explores the rising importance of gauze swabs in India’s healthcare ecosystem, their uses, manufacturing standards, pricing trends, and how the industry is responding to evolving medical demands.

2. Understanding Gauze Swabs: Composition and Purpose

A gauze swab is a small square or rectangular piece of woven cotton fabric used for various medical purposes, including wound cleaning, fluid absorption, and protection of open injuries. Its porous texture allows air circulation, which accelerates healing and prevents moisture buildup— a common cause of bacterial infections.

A gauze swab is a small, square piece of medical-grade cotton fabric that is woven into a meshlike structure. This design allows the swab to be highly absorbent, making it ideal for cleaning wounds, absorbing fluids, and applying antiseptics. Gauze swabs are commonly used in both minor and major medical procedures, from dressing wounds to controlling bleeding during surgery.

The primary function of a gauze swab is to provide a sterile barrier between the wound and the external environment, reducing the risk of infection. They are also used to absorb exudates, which are fluids that leak from wounds. In surgical settings, gauze swabs are often used to soak up blood and other fluids, helping to maintain a clear view of the surgical area.

Modern Gauze Swab Sterile products are crafted using high-quality cotton fibers that are bleached and sterilized under strict conditions. The edges are often folded in or stitched to avoid loose threads, ensuring safety during surgical use.

The significance of gauze swabs lies in their simplicity and versatility. They serve as the first line of defense in medical and surgical environments, helping doctors and nurses maintain aseptic conditions during treatment and post-operative care.

3. Sterile Gauze Swabs Uses in Surgical and Medical Care

Sterile gauze swabs uses are wide-ranging, spanning almost every department within a hospital—from operating rooms and emergency wards to outpatient clinics and dental offices. Below are some of the most common applications.

Sterile gauze swabs are used for various purposes in surgical and medical care, including cleaning wounds, absorbing blood and fluids, applying medications, and as a protective covering. Their primary roles are to provide a sterile barrier to prevent infection, manage wound drainage, and create a clean base for dressings, ensuring comfort and promoting healing:

a. Surgical Procedures:

During surgeries, sterile gauze swabs are used to control bleeding, absorb fluids, and clean wounds. Their high absorbency ensures a clear surgical field for surgeons to operate safely.

b. Wound Dressing:

In both hospital and home care settings, gauze swabs provide a clean, breathable covering for wounds, preventing infections and aiding healing.

c. Post-Operative Care:

After surgery, Gauze Swab Sterile products are applied to surgical incisions to minimize contamination risks and absorb any discharge.

d. Dental and Orthopedic Applications:

Dentists use sterile gauze pads during extractions and cleanings to manage bleeding, while

orthopedic specialists rely on them for dressing and cleaning bone-related injuries.

e. General Patient Hygiene:

In hospitals, gauze swabs are also used for cleaning and disinfecting the skin before injections or minor procedures.

f. Laboratory and Diagnostic Uses:

Gauze swabs are utilized in sample collection and cleaning medical instruments between tests.

The multiple Sterile gauze swabs uses make them an irreplaceable item in medical care—one

that ensures patient safety, reduces infection risks, and simplifies post-surgical recovery.

4. Manufacturing Standards and Quality Assurance

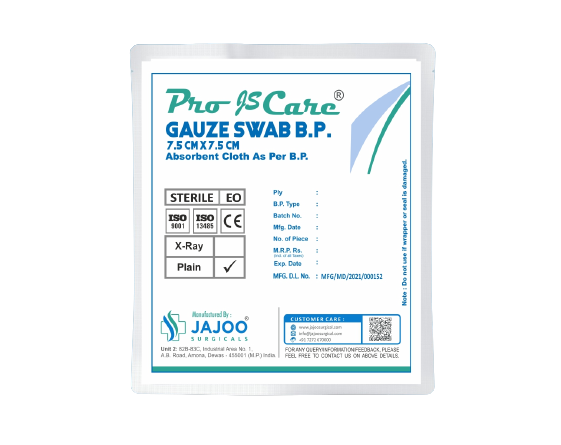

The production of gauze swabs requires adherence to rigorous hygiene and safety standards. Leading Gauze Swab manufacturers India follow strict international protocols such as ISO 13485, CE Marking, and QMS certification to ensure their products meet both domestic and global healthcare expectations.

Sterile gauze swab manufacturing standards focus on raw material quality, processing, and sterilization, adhering to pharmacopeia standards like those from the British Pharmacopoeia (BP). Key aspects include using high-grade cotton, thorough bleaching with hydrogen peroxide and demineralized water, precise folding to prevent loose threads, and sterilization via gamma radiation or ethylene oxide (ETO) to ensure sterility. Quality control checks cover absorbency, softness, and the integrity of the final product

Here’s how the process works:

a. Raw Material Selection:

Only premium-grade cotton that meets pharmacopeia standards (IP, BP) is used. The cotton

must be free of seeds, dust, and impurities.

b. Bleaching Process:

Cotton undergoes a controlled bleaching process using hydrogen peroxide to achieve high

whiteness without compromising fiber integrity.

c. Weaving:

The cotton is woven into gauze fabric with specific mesh counts to ensure optimal absorption

and strength.

d. Cutting and Folding:

The gauze fabric is cut into uniform sizes (usually 5cm x 5cm, 7.5cm x 7.5cm, or 10cm x

10cm), then folded and layered to form the required thickness.

e. Sterilization:

To create Gauze Swab Sterile products, swabs are sterilized using methods such as ethylene

oxide gas or gamma radiation. This ensures complete elimination of microorganisms.

f. Packaging:

Swabs are sealed in sterile pouches or blister packs under hygienic conditions, ready for

distribution to hospitals and clinics. Each batch undergoes stringent quality testing for absorbency, whiteness, weight consistency, and microbial safety before being approved for use.

5. Why India is Emerging as a Global Hub for Gauze Swab Manufacturing

The Indian healthcare supply sector has become a leading source for surgical disposables worldwide. This is largely due to the availability of high-quality raw cotton, skilled labor, and advanced production facilities. Gauze swab manufacturers India are leveraging these strengths to meet both domestic and export demands.

Key factors driving this growth include:

● Government Support: Initiatives like “Make in India” have encouraged local production

of medical disposables.

● Export Potential: Indian manufacturers are exporting to regions like Africa, the Middle

East, and Southeast Asia.

● Cost Efficiency: Low production costs allow Indian suppliers to provide competitive

pricing without compromising on quality.

● Technological Innovation: Automation and sterilization technologies have enhanced

product consistency and hygiene.

The rise of India’s medical textile industry has made it possible for healthcare institutions

worldwide to access reliable and affordable Gauze Swab Sterile products.

6. Factors Affecting Gauze Swab Price

The Gauze Swab price varies based on several key determinants:

a. Size and Ply Count: Larger swabs or higher ply counts (more layers) generally cost more due to increased material usage.

b. Sterilization Method: Sterile gauze swabs, which require advanced sterilization techniques, are priced higher than non-sterile ones.

c. Packaging: Individually packed sterile swabs are costlier due to the need for aseptic packaging materials and processes.

d. Cotton Quality: The quality of cotton used significantly impacts absorbency, softness, and ultimately, pricing.

e. Brand and Certification: Reputed gauze swab manufacturers India with ISO or CE certifications often price their products higher to reflect international quality assurance.

f. Bulk Orders: Hospitals and distributors often get discounted rates on bulk orders, reducing the per-unit Gauze Swab price.

Despite fluctuations, India remains one of the most cost-effective markets for sterile medical disposables, offering world-class quality at affordable rates.

7. Challenges Faced by Gauze Swab Manufacturers in India

While the industry is growing, manufacturers face several challenges that impact scalability and profitability:

a. Raw Material Availability:

Fluctuating cotton prices can increase production costs, affecting the Gauze Swab price in the

market.

b. Regulatory Compliance:

Keeping up with evolving healthcare standards and certifications can be time-consuming and expensive.

c. Counterfeit Products:

The market often faces an influx of low-quality, unsterile products that compromise patient safety and tarnish the reputation of genuine Gauze Swab manufacturers India.

d. Supply Chain Disruptions:

Delays in transportation or shortages in packaging materials can slow production and delivery timelines.

e. Sustainability Pressures:

Manufacturers are under growing pressure to adopt eco-friendly processes, which may involve additional investments in technology.

Despite these challenges, innovation and strict quality control continue to drive the success of Indian gauze swab producers on the global stage.

8. The Role of Sterilization in Ensuring Safety

Sterilization is the most critical step in gauze swab manufacturing. Non-sterile products pose a significant risk of infection during surgical or wound-care applications. Modern Gauze Swab Sterile products undergo one of two primary sterilization methods:

● Ethylene Oxide (ETO) Sterilization: A low-temperature method that effectively kills bacteria and spores without damaging cotton fibers.

These methods ensure that every gauze swab reaching the operating room is completely free of pathogens, ensuring patient safety and compliance with international healthcare standards.

9. Innovation and Future Trends in Gauze Swab Production

As medical science evolves, so does the demand for advanced and multifunctional surgical disposables. The Gauze Swab manufacturers India are adapting to these changing trends by integrating new technologies and materials.

Emerging Trends Include:

● Antimicrobial Gauze Swabs: Impregnated with silver or chlorhexidine for enhanced

infection control.

● Eco-friendly Materials: Use of biodegradable cotton and sustainable production

methods.

● Smart Packaging: Improved sterile packaging with indicators that change color to

confirm sterilization integrity.

These innovations not only enhance patient safety but also help healthcare providers achieve higher efficiency and reduce waste.

The Expanding Market: Demand Across Hospitals and Clinics India’s healthcare system has seen remarkable expansion, especially post-pandemic, with more hospitals, clinics, and diagnostic centers emerging across urban and rural areas. This has directly contributed to rising demand for Gauze Swab Sterile products.

Market Drivers:

● Increase in surgical procedures across public and private hospitals.

● Rising focus on infection control and hygiene standards.

● Growth in medical tourism, attracting international patients.

● Expanding network of primary health centers and emergency care facilities.

● Awareness about sterile products in wound management and home healthcare.

With healthcare expenditure expected to grow steadily in the coming years, the demand for sterile gauze swabs will continue to rise, creating opportunities for both established and emerging gauze swab manufacturers India.

11. Sustainability in Gauze Swab Manufacturing

Sustainability is no longer optional—it is a necessity. Manufacturers are adopting environmentally responsible practices without compromising product quality.

Key Sustainability Initiatives Include:

● Water and Energy Efficiency: Reducing water use in bleaching and dyeing processes.

● Eco-Friendly Packaging: Shifting from plastic to recyclable or biodegradable materials.

● Waste Recycling: Reusing cotton waste in non-surgical cleaning materials.

● Renewable Energy Adoption: Implementing solar-powered machinery and production units.

These initiatives not only support environmental goals but also strengthen brand credibility in both domestic and export markets.

12. FAQs: Everything You Need to Know About Gauze Swabs

Q1. What are the primary Sterile gauze swabs uses?

They are used for cleaning wounds, absorbing fluids, dressing surgical sites, and controlling bleeding during medical procedures.

Q2. Why choose Gauze Swab Sterile over non-sterile options?

Sterile swabs minimize infection risks and ensure safe use in surgeries and open wound treatments.

Q3. What determines the Gauze Swab price?

Size, quality of cotton, sterilization method, and packaging type influence the final cost.

Q4. Are Indian manufacturers compliant with global standards?

Yes, most leading Gauze Swab manufacturers India are ISO and CE certified, meeting international quality benchmarks.

Q5. How are gauze swabs sterilized?

Common methods include ethylene oxide gas sterilization and gamma irradiation.

Q6. What is the future of gauze swab production in India?

The future lies in automation, eco-friendly manufacturing, and increased export potential as India strengthens its medical textile sector.

13. Conclusion: A Growing Industry Shaping India’s Healthcare Future

The surge in India’s healthcare expansion has opened new avenues for medical textile products, especially gauze swabs. With hospitals performing thousands of surgeries daily, the need for reliable, sterile, and affordable medical disposables has never been greater.

Gauze swab manufacturers India have risen to this challenge, producing high-quality, certified, and sustainable products that meet global standards. From small clinics to large multispecialty hospitals, the use of Gauze Swab Sterile items has become indispensable for safe, efficient, and hygienic surgical care.

As innovation continues and awareness about sterile medical supplies grows, the demand for gauze swabs will only increase—solidifying India’s position as a leading global hub for medical disposables. Whether it’s understanding Sterile gauze swabs uses or evaluating the Gauze Swab price, one thing remains clear: this simple yet powerful product is a silent hero in saving lives and maintaining healthcare excellence every single day.